Cobra Biologics

Developing an industrial biologics manufacturing platform

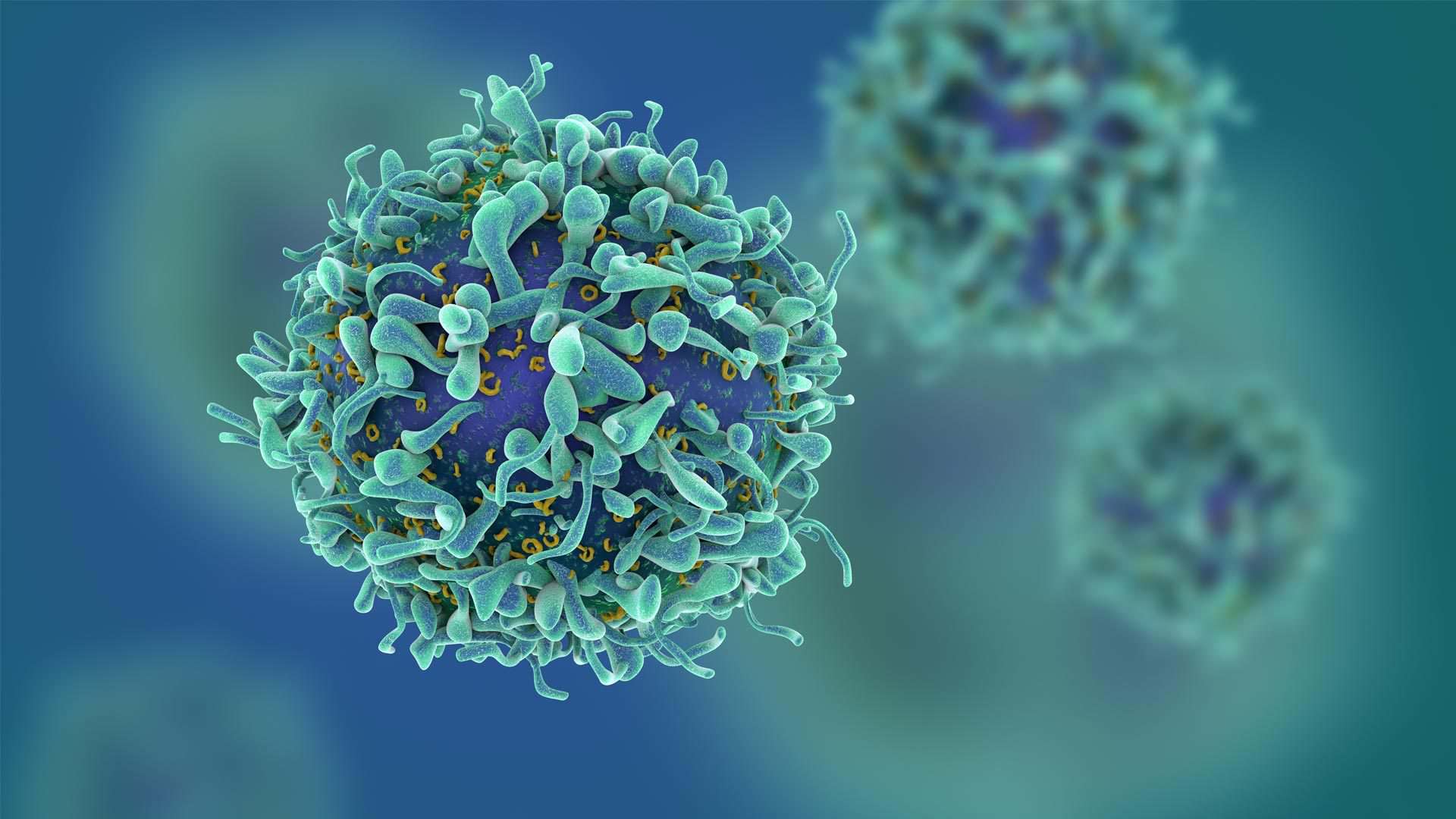

Development of an industrial manufacturing platform for adeno-associated virus (AAV) production

Gene therapy is a rapidly growing therapeutic area, with AAV being one of the main platforms being developed for commercialisation. The production of well characterised, high quality AAV vectors is critical for the success of gene therapy. This will be achieved by developing platform AAV manufacturing processes that are robust and scalable.

This project addresses the key barriers facing routine production of AAV by focusing on the development of a scalable platform process. The project had two partners; CPI and Cobra Biologics, and was supported by funding from Innovate UK through the UK Government’s developing regenerative medicines and cell therapies initiative.

Achievements

Inputs

- Provided open access to CPI’s state-of-the-art facilities

- Shared expert technical and industrial knowledge through collaborative development projects

- Provided project management and business support services

- Expertise in biomanufacture of gene therapy components

Outputs

- Advanced analytical tool kit consisting of conventional and high throughput techniques to support AAV in-process development and final product quality

- Robust 2D and 3D upstream process for AAV vector production at various scales through to manufacture

- Robust downstream process with contaminant clearance for AAV vector purification at various scales

- Quality by design (QBD) mapping for upstream and downstream processes of AAV manufacture

Outcomes

- Robust work flows and methods to support process development through to manufacture of AAV

- Optimising processes to reduce production costs of AAV

- Exemplification of collaborative project approach which would be applicable to other gene therapies and viral vaccines

- Identification of areas to target future development of AAV manufacture

The challenge

The gene therapy market is expanding extremely rapidly and set to reach $10 billion by 2025. The challenges facing industry include producing increasing amounts of high quality material to meet the rising demand of these therapies to address unmet medical need. Scalable, robust processes for multiple AAV serotypes meeting regulatory requirements are essential to growing this therapeutic area.

How CPI helped

The project aimed to develop a scalable manufacturing platform for selected AAV serotypes. CPI’s expertise and assets played a key role in the following areas:

- Optimised transfection and cell growth to achieve high titre vector production in both 2D and 3D cultures

- Designed and optimised novel work flows to support the downstream processing of AAV vectors

- Development of a high throughput analytical toolbox

Related

Technologies

Markets