Reducing the environmental impact of food waste

Food waste is not a new problem and could well be one of the biggest problems facing mankind today.

Technology and Innovation Officer (Formulation)

I felt like throwing things at the TV in March when I saw the news about household waste bins overflowing with unused food following the initial bout of panic buying at the start of the COVID-19 health crisis! Food waste is not a new problem though and could well be one of the biggest problems facing mankind today.

More than a third of all food produced globally never makes it to a plate, being either spoiled in transit or simply thrown out. This equates to around 1.3 billion tons of food worth nearly $1 trillion at retail prices — a massive market inefficiency not found in any other industry! Meanwhile, 800 million people go to bed hungry every night, yet could be fed on less than a quarter of the food wasted in the USA, UK and Europe each year.

As well the moral concerns, food waste is potentially catastrophic for the environment. Food that is never eaten accounts for 25% of all fresh-water consumption used in food production globally, and it takes a land mass larger than China to grow this amount of food each year. Much of this food waste goes to landfill where decomposes to create methane which is 23x more deadly than carbon dioxide.1 It’s even been said that if food waste were a country, it would be the third-largest emitter of greenhouse gases after China and the USA, equivalent to 3.3 billion tonnes of carbon dioxide per year.

Feeling a little uncomfortable yet? We can dismiss food waste as someone else’s problem but in the developed world, more than 50% of food waste comes from homes; the average UK household throws away £730 worth every year. We are potentially half the problem, but this means we can become half the solution!

Thankfully this is on the UK governments agenda, with £1.15 million of funding announced in March 2020 to tackle food waste in households and supply chains, with the first-ever Food Waste Action Week from Monday 11th May. So, asides from personally taking more responsibility for what we buy and use (and I’m sure many of us have become a little more creative recently in what we cook to ensure we don’t waste an ounce of anything), what else can be done to address these issues and what role can CPI play here?

Extending the shelf life

Developing improved coatings for packaging

No doubt we have all found ‘that’ can of John West tuna at the back of our kitchen cupboard and questioned whether we should brave eating the contents. Food cans have an internal polymer coating to protect from the corrosive nature of the food or drink, so improving the barrier properties of such coatings could extend the shelf life of canned goods.

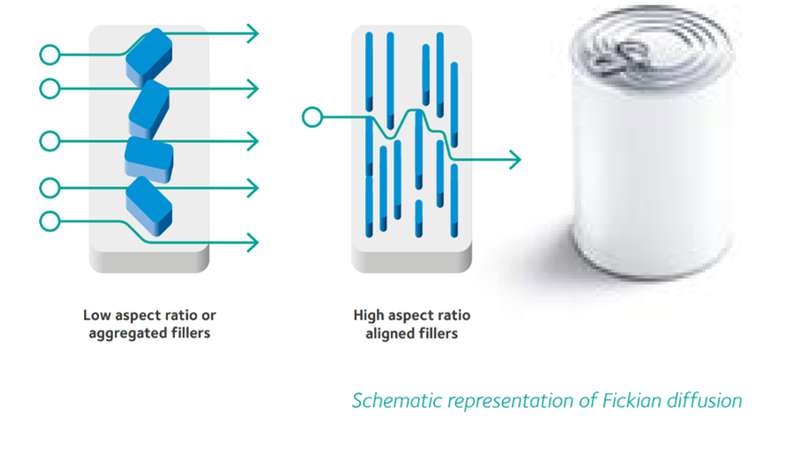

High aspect ratio filler materials have long been known to frustrate the permeation of solvents through polymeric films as the resulting tortuous path increases the film’s barrier properties. These would therefore be good alternative materials for coatings with improved barrier resistance without the regulatory concerns carried by some of the chemicals currently used. This was the focus of the HERMETIC Innovate UK project; CPI’s role was to develop a new class of thin film coatings for packaging with a high barrier to corrosive solutions, being food contact compliant with low to zero dissolution into the food, mechanically ductile and with a viscosity suitable for draw down or spray coating.

CPI successfully formulated nanomaterials into a resin, using cold plasma functionalization, solvent addition and high shear to optimise and give a coating with improved barrier properties, demonstrated through the corrosion testing via optical microscopy and barrier properties through Electrical Impedance Spectroscopy.

HERMETIC brought together an entire supply chain with partners Thomas Swann (providing nanomaterials), AkzoNobel (supplying resins), and Crown Packaging who will use the novel formulation to coat their metal packaging.

Polymer films are used to coat paper food packaging, but the need to save costs and address environmental concerns as described above is leading to a reduction into the volume of polymer used and ultimately thinner polymer films which are more sensitive to defects NanoMend, an FP7 funded project, developed technologies to detect and correct micro and nano-scale defects within films, without reducing production efficiency, leading to enhanced film quality, yields and lifetime, and therefore enabling robust polymer films for food packaging.

How else could nanomaterials help?

There are other examples of where nanomaterials could help reduce food waste issues, such as improving the gas barrier properties of plastic or providing antimicrobial properties which contributes to keeping food fresh during storage, and in nanosensors which can detect gases given off by food as it spoils, to give real-time information on food quality. Excitingly, these are all areas in which CPI has relevant capability to help companies innovate, but we need to ensure that the risks of nanomaterial migration into foodstuffs is properly assessed, and consider carefully how their use affects the materials recycling.

A look at smart packaging

Smart Packaging

Packing is generally treated as a cost which needs to be reduced. But what if the packaging can give added value and potentially even lead to cost savings?

Active Packaging — Development of time and temperature responsive smart labels

The sell-by, use-by and best before dates used for perishable goods currently provide insufficient information to consumers about the shelf-life status and degradation, but what if the packaging included smart labels which alert consumers to the goods’ condition as it deteriorates, or even provide real-time information on a product’s condition throughout its supply chain journey?

Working in collaboration with SMEs Intray Limited and Mexar Limited, CPI was part of the TTI labels Innovate UK project to enable the production of Time Temperature Indicator (TTI) labels which use a traffic light system; when the label turns amber this is a call to action to use the food goods and when it turns red this notifies consumers that the product is no longer fit for use or consumption. CPI helped develop printable acid-containing hydrogels, characterised the diffusion/timing behaviour of prototype labels, used computer modelling to predict label timing for different conditions and helped evaluate the robustness of the labels, enabling InTray to carry out market trials.

Intelligent Packaging

Electronic tags, chips & sensors can be used to monitor the external environment in order to reduce supply chain losses. Picture foodstuffs travelling along the new silk road linking China to the Middle East and Europe, traversing harsh terrain and severe weather with temperatures reaching ‑40 °C in winter; the need to sense everything from temperature to humidity to atmosphere composition through to shock to tampering becomes crucial for optimizing the shelf life of perishables, with any deviation from the required transport conditions being quickly identified and rectified from afar.

One of the key challenges is around making these sensors cheap enough, being able to integrate them and then demonstrate at scale. This is where CPI’s expertise in flexible hybrid electronics comes in – combining the high functionality of silicon integrated circuits (chips) with, flexible substrates, antennas and conductive traces, to enable embedded electronics in a range of packaging types, coupled with a route to high volume production. Small batches of circuits can be designed, tested and assembled which allows pre-compliance testing and proof of viability before circuits are batch screen printed in their hundreds using conductive inks (which CPI can also support optimise). Once these prototypes are validated, they can be upscaled towards roll to roll printing, assembly and converted into product such as smart tags or labels. However, within the food and drink industry, the cost of smart intelligent packaging is still considered to be too high to outweigh the benefits it brings in all but higher cost items; it’s just not commercially viable to add 15p cost onto a cucumber costing 50p if it only adds 3 extra days onto the 10-day shelf life of a 50p cucumber, when the same effect could be delivered with 1p worth of biaxially oriented polypropylene film!

Large scale trials are needed in real supply chains to understand how much value can be created by reducing waste; this is where CPI can help through scale production of smart intelligent packaging, but we have another ace up our sleeve, PragmatIC who has worked with CPI for several years now. They are developing a large-scale production to manufacture plastic flexible integrated circuits to enable smart tags to be produced at a tenth of the current costs (volume cost for RFID/NFC tags is several pence each). Their current chip functionality is low and doesn’t support sensing but even with the track, trace and security features they offer, this can help to reduce waste through better supply chain management and control. If you know where everything is at all times, you can have more efficient supply chains and therefore reduce waste.

CPI was also a partner in the ReMediES project, funded through the Advanced Manufacturing Supply Chain Initiative, to develop flexible smart tags for temperature and humidity monitoring and global track and trace of medicines; the same principles can be applied in the food supply chain. As a work package leader, CPI, alongside partners including GlaxoSmithKline and AstraZeneca, oversaw the development and scaling up of agile, smart drug packaging concepts incorporating printed electronics. CPI developed prototype smart labels capable of monitoring and tracking environmental conditions, through a clinical supply chain, with the data transferred to GSK in real-time via a mobile phone app across the Internet of Things.

Another example is the Horizon 2020 funded NECOMADA project, focussed on lowering the cost of smart devices through the development of new nanomaterial-based conductive inks and fast-cure adhesives that improve the effectiveness, productivity and speed of printed electronics manufacturing. A pilot line was developed at CPI that integrates the materials, printing and component placement capabilities that are essential for high-volume device manufacture and presents a reconfigurable open-access platform for companies to use when trialling their materials and flexible electronics products. One demonstrator resulting from this was smart tags for use with food packaging which can be read by a fridge or freezer and provide consumers with an up-to-date inventory of the food stored within in it along with information on best-before dates, as well as enabling online access via phone during shopping, in order to reduce food waste by improved food management.

Creating value from food waste

It’s unlikely that we can stop food waste altogether, but there are various routes to reuse or valorise this waste into something with value, such as high quality high quality food supplements, pharmaceutical grade compounds, bulk replacers to reduce sugar and increase fibre and as a fuel source. An example of this was the PlasCarb H2020 funded project, which developed a microwave plasma process to transform the biogas generated by anaerobic digestion of food into renewable hydrogen and high-purity graphitic carbon for use in e.g. inks, coatings, battery cathodes and even medical applications such as bone tissue engineering,

Plastic food packaging

We’re all aware that this is another major environmental concern. Plastic is ideally suited for food and drink as it’s cheap, capable of being made into any conceivable shape, strong and durable. Since the 1950s an estimated 8.3 billion metric tonnes has been produced, but it takes more than 400 years for plastic to degrade, and as 79% is thrown away (with only 9% per cent recycled and the rest incinerated), plastic levels in our oceans are escalating out of control. Without intervention, it’s estimated that by 2050 there will be more plastic than fish in our oceans, 99 per cent of all the seabirds on the planet will have consumed some, and there will 12 billion tonnes in landfill, about 35,000 times as heavy as the Empire State Building.

But we’re OK if we put our plastic in the recycling bin, right? Not if reports are correct that, because we can’t process it in the UK, we’re sending two-thirds of this overseas, where it can’t be guaranteed that recycling is done safely and effectively, plus the obvious knock-on environmental impact of increasing shipping. Often what’s sent is also contaminated (i.e. mixed with non-recyclables) or not economically viable to recycle, so, unfortunately, it just ends up being another countries waste problem.

There are some signs that the UK is starting to address these issues with the government’s Resources and Waste Strategy which sets out how to double resource productivity and eliminate avoidable waste of all kinds (including plastic waste) by 2050, by putting a legal onus on those responsible for producing damaging waste to take greater responsibility. In the meantime, CPI has supported a number of projects aimed at reducing the environmental impact of plastics.

CPI has capability to support the recycling and reuse of plastics, such as process development to separate and purify waste plastics, solvent recovery of waste plastics back to near virgin quality and remanufacture from waste plastic, through filament to 3D printed products or for use in composites. One company CPI is working with is Worn Again Technologies, helping them to design and build a new pilot plant which will separate, decontaminate and extract PET polymer and cellulose from end of life PET bottles/packaging, and poly-cotton fabrics back to their constituent components to provide new feedstocks for onward polymerisation i.e. making into new clothing or plastic bottles.

CPI is also part of a consortium developing biodegradable food packaging, funded by Innovate UK, ENVPAC. Although biodegradable plastics are widely available, these have poor thermal and mechanical stability, may only break down in the presence of oxygen and temperatures well in excess of 50 °C and other materials which claim to be biodegradable may only degrade to microplastics which have even more potential to impact aquatic life. CPI has been developing extruded blends of commercial biodegradable polymers to give the required physical properties (measured via tensile testing and dyfnamic mechanical thermal analysis) alongside biodegradability testing representing home composting and sea water environments. These blends will be thermoformed into food packaging by partner iPAC. Other partners Cranswick and Avondale Foods supply 600 million packaged foods to all UK Supermarkets (for meat or salad/vegetables) so are sufficiently influential to disrupt status quo in the packaging industry.

CPI has also worked with Biome Technologies, a company developing novel biomanufacturing and polymerisation processes to create bioplastics which are made from sustainable plant. CPI has supported the company with proof of concept testing and developing a roadmap to guide their journey to commercialisation.

Our planet our responsibility

We all need to take responsibility for the environmental impact we make on our planet; unfortunately, we don’t live in a perfect world, and there will be those who are less prepared than others to make the effort to minimise food and plastic use and waste. But by playing our part in helping drive innovative solutions to these problems we can hopefully bridge the gap between those who do and those who don’t!

Discover how we support companies in their sustainable polymers, plastics and packaging innovation.

Enjoyed this article? Keep reading more expert insights...

CPI ensures that great inventions gets the best opportunity to become a successfully marketed product or process. We provide industry-relevant expertise and assets, supporting proof of concept and scale up services for the development of your innovative products and processes.