A smart approach to pharmaceutical packaging that adds value

How the internet of things and intelligent packaging could revolutionise pharmaceutical manufacturing and healthcare as we know it.

Director of Marketing Communications

The Internet of Things is a concept that is cropping up more and more frequently across mainstream media, trade press, and even as a feature of national innovation strategy. The term refers to a world in which everyday physical objects are embedded with electronic functionality, enabling them to communicate to the user and exchange data with other smart objects wirelessly over the Internet.

The hugely successful Nest thermostat, which learns the heating preferences of its users when they are at home, turns off automatically when they are not, and can be controlled at distance from the user’s mobile phone, is a great example of the market potential for internet of things technology that simplifies and streamlines the management of everyday tasks.

The packaging industry is responding keenly to the possibilities that embedded smart components can offer. Whilst the umbrella term “smart packaging” is used regularly, there are different sub-sets of packaging embedded with electronic functionality. These are:

- Smart packaging: Any packaging that serves a purpose other than containment and protection.

- Active packaging: Packaging that actively improves the product or its potential use.

- Intelligent packaging: A packaging system that transmits or gathers data or information about the product.

Much of the work going into electronically capable packaging within the FMCG sector focuses upon the development of smart packaging that offers fun features to encourage brand interaction, often used in conjunction with a consumer’s smart phone. For example printed panels on packaging which light up and display moving or flashing images, or which enable the consumer to collect loyalty points when scanned with their mobile phone, as well as interactive or flashing electronic point of sale advertising to attract shoppers at the point of making their selection from the shelves of the supermarket.

Beyond these fairly simple initial applications, highly functional, economic, quality control and sustainability benefits can also be realised. For example intelligent food packaging that indicates whether its contents have passed their use by date is under development, and could help to achieve real reductions in the high levels of food waste currently experienced in the UK.

There are significant opportunities within the healthcare and pharmaceutical market for printed electronics to provide substantial value, from devices worn on or inside a patient’s body to monitor their physical condition, to bio-sensors which can be utilised in in-vitro diagnostic devices to test samples from the human body for infection, and to diagnose medical conditions and monitor drug therapies, as well as pharmaceutical packaging.

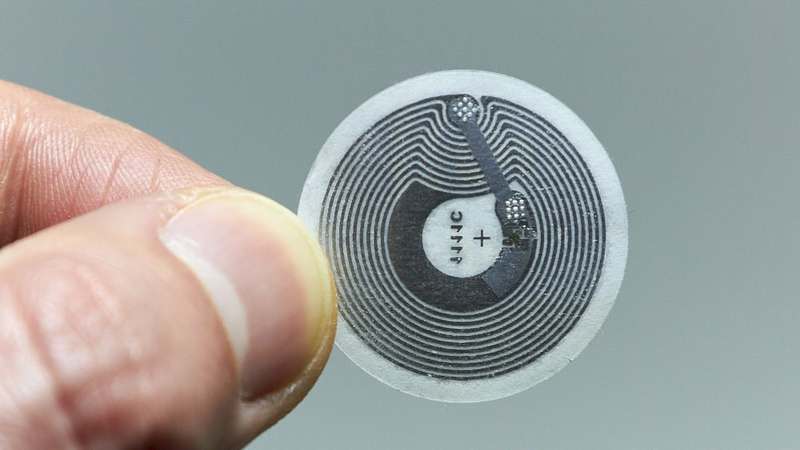

Intelligent packaging technology usually works by embedding low cost printed sensors, or near field communication (NFC) antennas, into the box or packet. NFC antennas are powered by induction, which can be tracked remotely, or read by mobile phones or scanning devices within a particular range.

In the pharma industry, smart packaging can provide important information about, and monitor the conditions a product has been exposed to during its journey through the supply chain. At present, once a consignment leaves the factory, with the exception of location tracking, there is no real visibility as to what happens to it in the time leading up to its arrival at the point of delivery.

The incorporation of printed sensors and NFC antennas within packaging facilitates the monitoring of environmental conditions such as temperature, shock, and humidity in real time, to provide unequivocal evidence of quality. This will be of great benefit to an industry where consumers and brands face the risk of genuine harm from improperly packaged goods, expired products, and improper use.

Smart packaging can provide consumers with a better understanding of a product and how to interact with it safely, for instance by communicating with technology in smartphones, tablets, and other Wi-Fi-enabled devices to remind a patient to take their medication, and to supply a dosage schedule for attaining optimum results.

This data could be shared with the patient’s doctor, enabling them to monitor treatment plans and print repeat prescriptions without the patient having to formally request them. This will be particularly important for facilitating the shift towards the growing use of personalised and stratified medicines, the use of which involves breaking complex conditions down into smaller subtypes based specifically on their underlying causes, then targeting those causes at a molecular level with biopharmaceuticals.

Unlike the “one size fits all” drugs which are currently commonly used, the dosage and type or combination of precision drugs required will be specific to individual patients or sub-types, so smart packaging with the ability to provide patients with all of the information they require could reduce unnecessary face to face appointments, providing some breathing space for already overburdened health service practitioners, and reduce the dangers involved with improper use.

It is also possible to use printed sensors to identify and guard against counterfeiting and third party interference, for instance by changing colour upon the happening of shock or certain temperatures. This is particularly advantageous in the developing world, where there are known problems with drugs being tampered with, or swapped for cheaper, less effective drugs, and subjected to non-compliant storage and handling. As with food packaging, smart packaging can monitor oxygen and moisture levels within packaging in order to communicate when a drug is no longer fit for consumption.

Whilst there has already been some uptake of smart packaging solutions within the pharma industry, most notably the smart e‑labels produced by Schreiner MediPharm, which provide some of the anti-counterfeiting and intra-logistics benefits described above, there is currently no fully developed smart packaging supply chain.

Mass market adoption of the technology will only occur once there is a cost-effective production supply chain in place that enables printable electronics to be incorporated for roughly the same costs of production. Cost is a particularly prohibitive issue within the commercial drugs market, where profit margins are often low. In the past, manufacturers have focused on creating the cheapest and easiest packaging solutions so they can inject as much capital as possible into product development. Smart packaging requires a different approach —developing packaging as part of the overall product design rather than as a mere afterthought, or result of convenience or necessity.

European funded research and development projects, such as CPI’s SCOPE and REMEDIES, are underway to address this issue, by identifying new processes, equipment, and applications which will enable high-volume manufacturing of billions or even trillions of printed electronic components that incorporate NFC technology. For the supply chain to be genuinely viable, highly automated and high speed integration techniques that use generic equipment will need to be used, and production costs of <1 cent per NFC tag achieved. Funding has been made available for a collaborative R&D project to specifically establish the framework required for smart pharmaceutical packaging, with the aim of ensuring that the UK is leading from the forefront of this industry.

A key part of developing the as yet unestablished supply chain will be setting the regulatory framework for intelligent pharmaceutical packaging. The existing EC regulations describing what must appear on commercial pharmaceutical packaging will most likely need to change, and harmonise with the regulatory framework of other countries too, in order to facilitate a global shift towards adoption of smart packaging technology.

Perhaps the biggest potential barrier to pharmaceutical smart packaging is also the most economically valuable opportunity presented by this shift in technology. The data associated with smart packaging could provide a wealth of information about users’ habits and the way that they interact with and consume their medication, gathered in a non-obtrusive, highly streamlined manor.

However as precision medicines become more mainstream, and the data that is handled and gathered becomes more and more personal, patients may not be comfortable with their information being collected and shared. Issues as to ownership of data may also arise: Do healthcare professionals own the information about their patients’ treatment schedule, or does the drug manufacturer? These questions will need to be resolved before the packaging can be rolled out to full effect.

A final challenge to be considered is the process for disposal. When most people finish a course of medication they discard the package or bottle because they no longer need it. However sensors and other printable electronics have value that should be reused if the components are to achieve their full and useful life span. Disposal practices and procedures will need to be developed, implemented, and overseen, to ensure that a cost-effective, sustainable solution can be realised.

In many cases, the task of developing effective recycling programmes for these electronics will fall to regulatory officials, but this is unlikely to happen until the technology becomes more prevalent in the marketplace, leading to a “chicken and egg” scenario in terms of the need to establish the supply chain.

The potential benefits presented by pharmaceutical smart packaging are undeniable, and there is a real chance that the technology will add real value to the packaging and healthcare industries in the near term. The key to ensuring that this is possible will be developing a supply chain over the coming years that is robust enough in terms of volume, speed, and price, to facilitate mass market adoption. UK industry and academia are aware of the opportunities this industry presents, so it is likely that we can will see the results of the R&D time currently going into developing the technology in the none too distant future.

Enjoyed this article? Keep reading more expert insights...

CPI ensures that great inventions gets the best opportunity to become a successfully marketed product or process. We provide industry-relevant expertise and assets, supporting proof of concept and scale up services for the development of your innovative products and processes.