The Medicines Manufacturing Innovation Centre welcomes CME as latest partner

20 Jan 2022

CME, a provider of automation solutions and services to the pharmaceutical sector, will lend its automation and machine building expertise to the Medicines Manufacturing Innovation Centre to create an automated clinical trial packing and Qualified Persons (QP) release platform.

The Medicines Manufacturing Innovation Centre is a collaboration between industry, government and academia to develop, prove and commercialise disruptive digital manufacturing technologies for the pharmaceutical industry. Led by CPI, the collaboration operates a model of Grand Challenges that bring together the pharmaceutical industry and supply chain to identify and overcome major industry hurdles to reduce the time, resources, and cost of medicines manufacturing to ultimately deliver benefits to patients.

CME joins Grand Challenge 2 to support the pharmaceutical industry with transitioning to a ‘Just in Time’ approach for clinical trials.

Current processes for clinical trials rely on a ‘Just in Case’ approach, which often leads to drug overproduction due to the difficulty in accurately predicting patient demand. Transitioning to the ‘Just in Time’ approach will result in an agile and responsive supply chain that will be able to respond to real demand.

CME will support Grand Challenge 2 in its goals to facilitate innovation through automated technology, integrated automation, modular design, and digitisation of the Pharmacy Automation for Clinical Efficiency (PACE) platform.

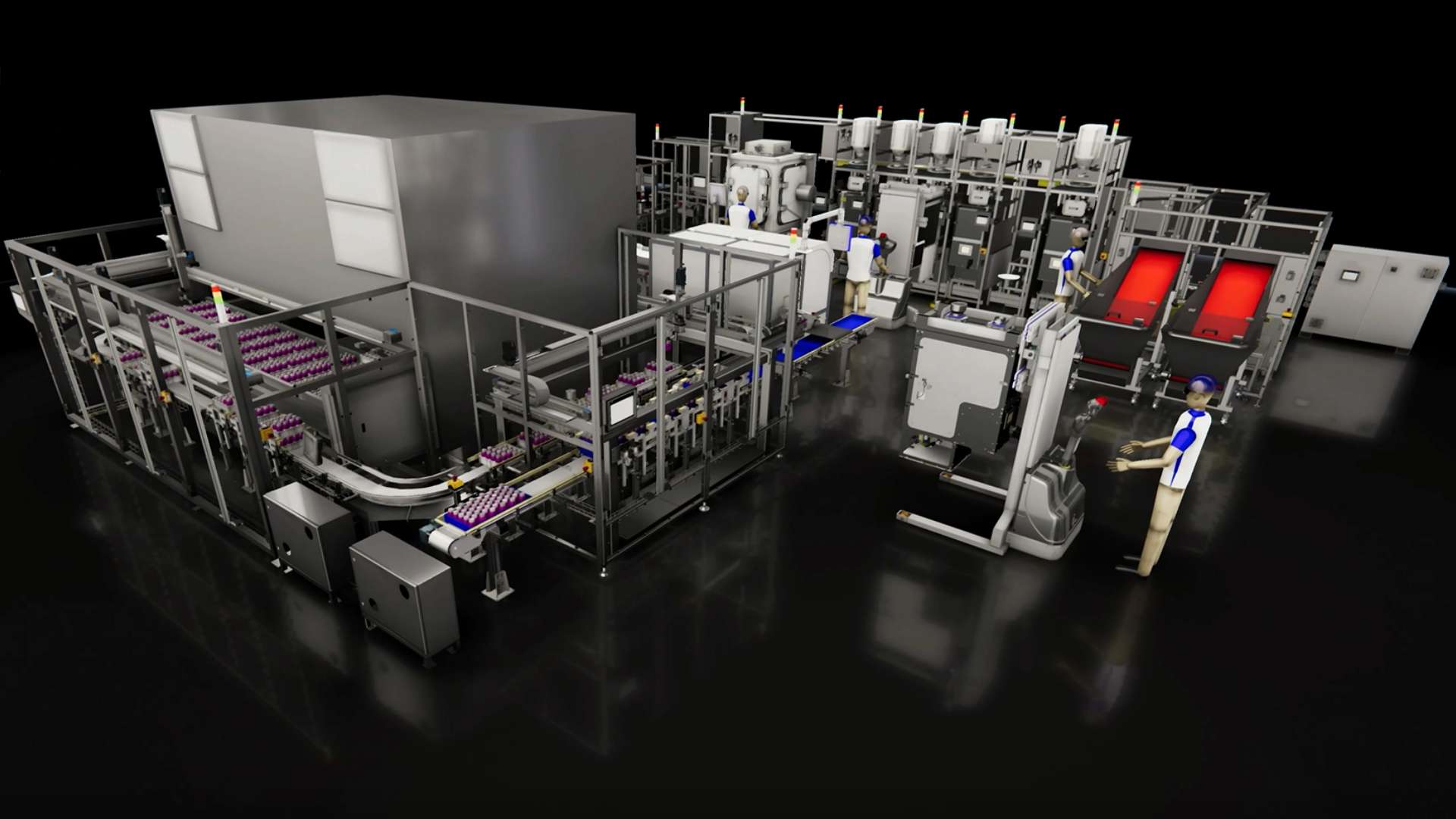

The PACE platform is a digitally enabled automated bottle packaging line that can fill tablets and capsules with custom amounts of drug compounds. One key innovation is the modular system design, allowing multiple drugs to be manufactured and packaged in the same facility without cross-contamination.

The design of the digital automation on the platform will enable Quality Teams, specifically those in the QP role, to monitor and release batches in real-time, resulting in less waste and reduced costs.

The project, which began in April 2019, is already progressing well and the packaging line, which has been built at CME’s facility in Somerset, is currently going through factory acceptance testing.

John Arthur, Director of the Medicines Manufacturing Innovation Centre, said: “CME’s expertise and capability in this field are a huge asset to this exciting, collaborative project and we are delighted they have joined us. Delivering innovation in PACE to reduce waste, risk and cost is a key objective for the Medicines Manufacturing Innovation Centre and our partners, and we’re looking forward to the line being completed later this year.”

Paul Knight, CEO of CME, said: “In just 3 years, the Medicines Manufacturing Innovation Centre has had a significant impact on the pharmaceutical industry. CME is delighted to come on board as the custom automation partner of the centre to provide design consultancy on custom robotics and automation.”

We are actively seeking new partners, both SMEs and large corporations, to maximise the impact of this innovative platform for drug manufacturing. We encourage interested companies to get in touch at www.uk-cpi.com/contact.

Let’s innovate together

To find out more about how we can work together, please enter your details below.