How sustainable fashion and science are joining forces

Sustainability is a major trend that is changing the landscape of the textiles market, with a number of companies pledging an increased focus in this area.

Principal Strategic Opportunities Manager

In recent years sustainability has taken centre stage as one of the earth’s most pressing issues, and few industries have needed to look at themselves more closely than the fashion industry.

The way we currently design, manufacture and use textiles is wasteful and polluting to our planet. Large amounts of non-renewable resources are being extracted to produce clothes that are often used for only a short time, after which the materials are incinerated or sent to landfill.

In addition to climate change, the fashion industry also contributes to the decline of biodiversity on the planet through land conversion and deforestation.

Combatting climate change, pollution and the decline in biodiversity is a global priority, and the need for the fashion and science based industries to join forces is stronger than ever with collaboration between the two offering the opportunity to disrupt tomorrow’s fashion through materials innovation and enable a sustainable future.

Sustainability is a major trend that is changing the landscape of the textiles market, with a growing number of companies pledging an increased focus in this area.

The Stella McCartney brand has a policy of never using leather in their products and supports the use of innovative and more sustainable materials for the manufacture of shoes and bags.

Luxury conglomerate Kering (owner of Alexander McQueen, Saint Laurent, Balenciaga and Gucci) have a Materials Innovation Lab that invests in identifying sustainable raw materials that meet the high standards of quality required by luxury goods and have eradicated PVC from 99.8% of their products while creating an extensive library of sustainable materials.

Luxury fashion house Gucci has eliminated the use of animal fur from their collections, and the company’s Florence based Artlab supports technology innovation and sustainability through research into new material development.

The demand for sustainable fashion is also evident in the high street. By 2030 H&M is aiming to use 100% recycled or other sustainably sourced materials, and by 2040 aims to have a net positive impact on the climate.

Social media is driving the demand for sustainable fashion further, as platforms such as Instagram can engage and influence consumers, promoting a more sustainable lifestyle and increasing supply chain transparency and brand awareness.

As well as many companies phasing out the use of fur, there are also signs that consumer opinion towards leather may be shifting. Interest in non-animal textiles is rising, with the vegan leather market set to be worth $85 billion globally by 2025.

Leather has long been associated with a perception of luxury as it offers a superior feel to synthetic alternatives, is aesthetically pleasing and also highly durable. Leather is often produced as a by-product of livestock farming, which is responsible for an estimated 14.5 — 18% of global greenhouse gas emissions[1, 2].

This equates to more than the estimated 14% of total emissions from global transportation. Other environmental considerations associated with leather production are the energy and water requirements of leather tanneries, as well as water pollution that may result from the chemicals used in the tanning process.

Alternatives to animal leather can be composed of a range of materials, however many synthetic leather substitutes are made from plastic, with the two used most commonly being polyvinyl chloride (PVC) and polyurethane.

PVC is made with chemical ingredients including chlorine and petroleum, neither of which are biodegradable nor environmentally sustainable. Leather substitutes have a relatively short lifespan and are discarded more rapidly than traditional leather products, which further contributes to the problem as they are not degradable and end up either as landfill or being incinerated.

Filling landfill with clothing and textiles costs the UK alone an estimated £82m annually, and fashion waste is predicted to cost the UK economy £4.48bn by 2050 unless recycling efforts are significantly improved. To combat the effects of waste from fast fashion, there is a need for more biodegradable textiles that can break down into non-toxic components.

On top of climate change and excessive waste, the level of biodiversity on the planet is declining at an alarming rate, with ecosystems, species and populations of plants and animals deteriorating or vanishing. Habitat loss is a significant contributor to the decline in biodiversity, and the leather industry is a driver of this with around 26% of the earth’s ice-free surface being used for livestock farming and 33% of croplands used for livestock feed production.

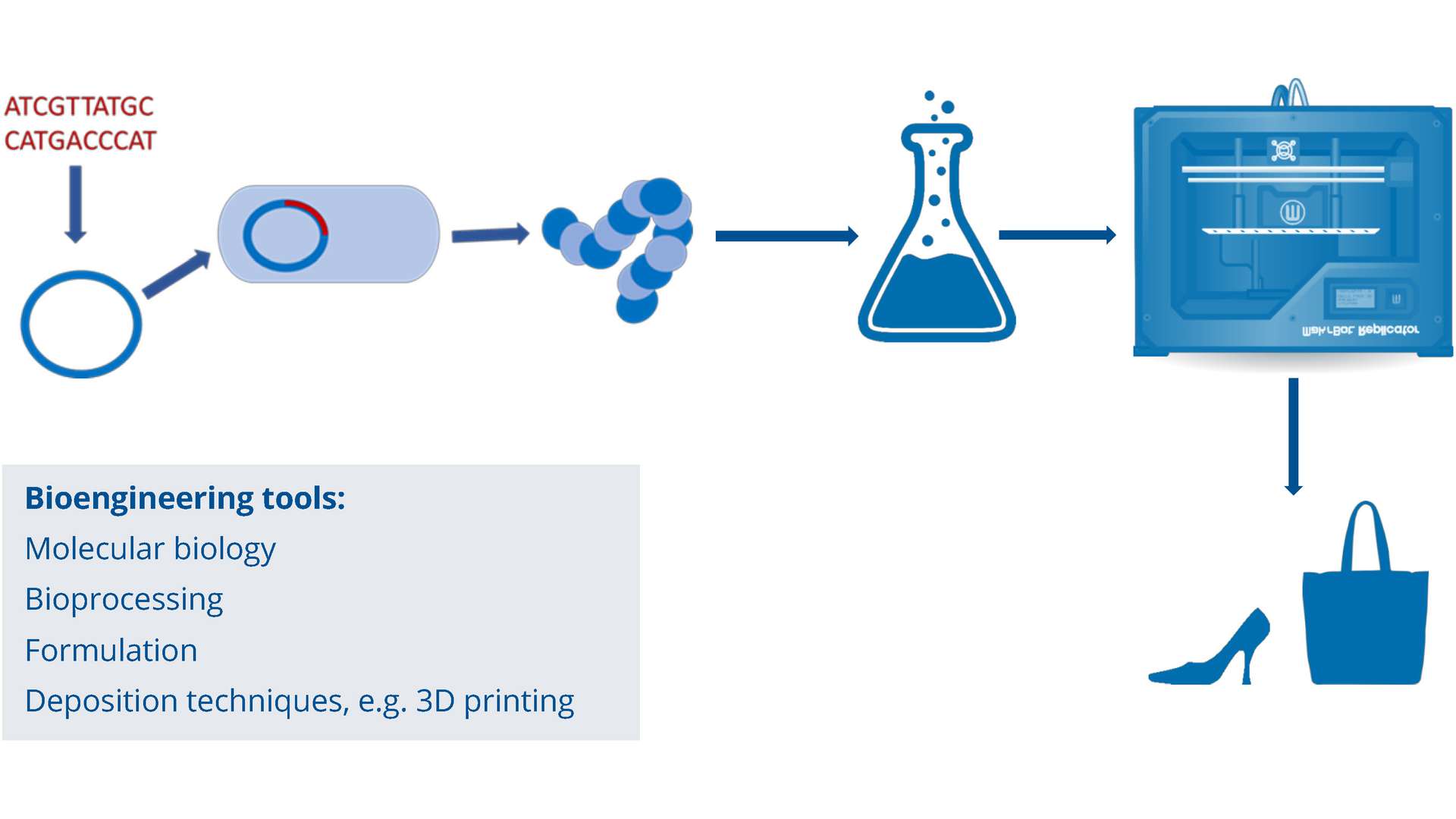

So how can science help? Bioengineering the next generation of textiles

Bioengineering is emerging as a promising tool for materials innovation. It provides the opportunity to create commercial scale biomaterial production, revolutionising the textile supply chain to provide affordable, biodegradable and sustainable textiles that have the same sensory and functional characteristics as an animal-derived product such as leather, or materials with novel engineered aesthetic and functional properties.

At the molecular level, animal materials are composed of protein building blocks. For example, leather is composed primarily of collagen and elastin, fur and wool are made up of the keratin protein and silk is composed of a protein called fibroin.

Through engineering biology and recombinant DNA expression we have the opportunity to create materials not simply inspired by biology (e.g ‘pleather’) but fabrics that are composed of the same natural protein building blocks and have the same tactile and sensory properties as animal-based materials.

Bioengineering enables animal proteins such as collagen and keratin to be made using microorganisms such as yeast or bacteria that have been engineered to contain the gene encoding the desired protein. The recombinant microorganisms will then make a protein that is identical to those made in animals and can be grown to a significant scale meaning large scale production of animal proteins is possible.

Companies working in this area include Bolt Threads who have developed MicrosilkTM based on recombinant spider silk and Modern Meadow who are working on bioengineered leather.

Production of animal products using this approach helps to address concerns associated with traditional agricultural methods including sustainability, environmental impact, animal welfare and public health and has the potential to dramatically transform the production and supply chain of textiles.

This includes leather, silk, wool and fur, especially when coupled with material formulation technologies and deposition techniques such as 3D printing. When the materials are no longer useful they have the potential to biodegrade, meaning less waste going to landfill.

Although the field of bioengineered textiles shows great promise there are still a number of challenges to overcome to enable the technology to become mainstream including bioprocess development, optimisation and scale-up for producing the protein of interest, formulation optimisation, creating the structure/architecture of the final material and ensuring a clean and sustainable manufacturing process.

Discover how we support companies in their sustainable clothing and textiles innovation.

References

1. Melissa Rojas-Downing, M., Pouyan Nejadhashemi A., Harrigan, T. & Woznicki, S.A. (2017) Climate change and livestock: Impacts, adaptation, and mitigation. Climate Risk Management, volume 16, 145 – 163

2. Steinfeld, Henning (2006) Livestock’s long shadow: environmental issues and options. Rome: Food and Agriculture Organization of the United Nations

Enjoyed this article? Keep reading more expert insights...

CPI ensures that great inventions gets the best opportunity to become a successfully marketed product or process. We provide industry-relevant expertise and assets, supporting proof of concept and scale up services for the development of your innovative products and processes.