Transformative health, medical and wellness technologies

Solving HealthTech scale-up and adoption challenges to meet global healthcare needs.

Revolutionising healthcare

Our expertise and facilities transform ideas into market-disrupting medical devices, wearables, and diagnostics that improve lives.

-

Push the boundaries of manufacturing

-

Make wearables more wearable

-

Diagnose earlier and more accurately

-

Targeted, stratified and personalised therapies

-

Internet of Things technologies

-

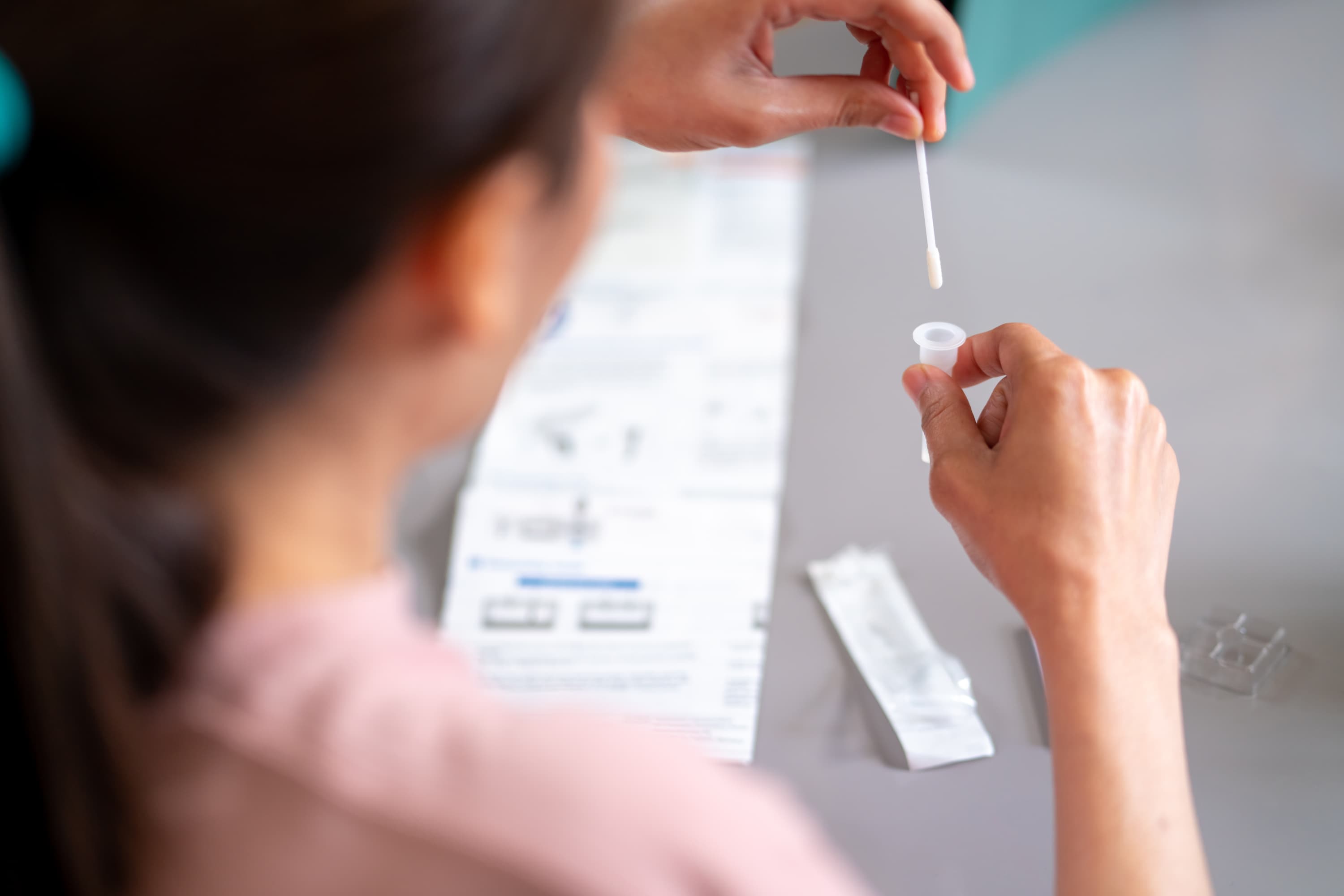

Tests closer to point of care

In vitro diagnostics

Accelerating the development of more accurate and affordable solutions from lab bench to patient.

Internet of Medical Things

Developing smart technologies that defy boundaries to connect medical devices and bring digital HealthTech solutions to patients.

Medical devices

Fast-tracking MedTech from concept to adoption to add value and benefit patients.

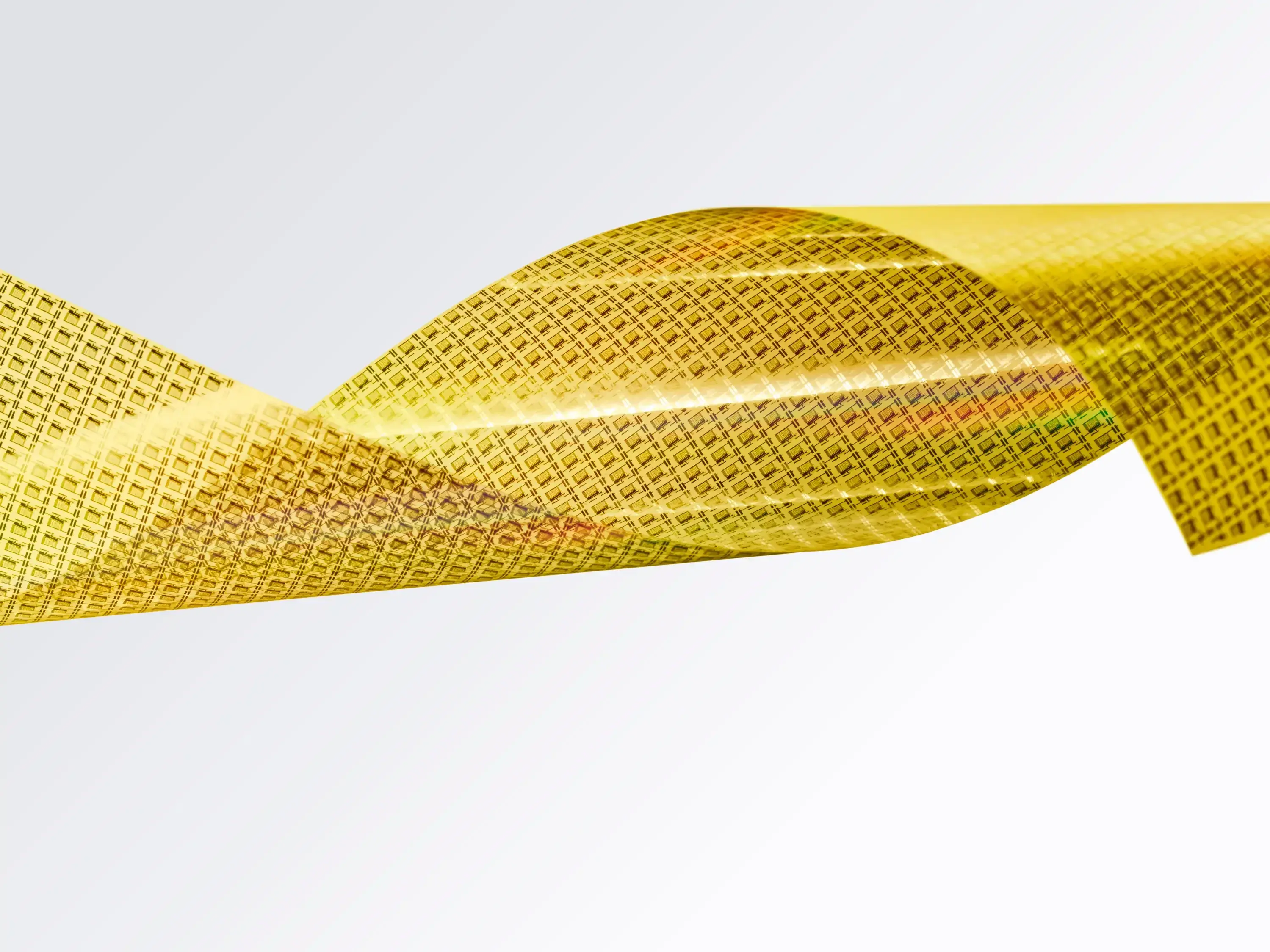

Wearable technology and health monitoring

Wireless communications and lighter, more flexible electronics to develop smart fabrics and miniaturised sensors for next-generation devices.

Drive your innovation forward

Work with us to defer capital and workforce investments until your product or process is proven at scale.

-

Find the right support

- Receive support from our multidisciplinary experts, and connect with our network of investors and partners.

-

Access world-class facilities

- Receive access to specialist innovation facilities for R&D, process development and scale-up work.

-

Work the way you want

- Fully customised, flexible projects and service options to fit your specific needs.